How to select the right bucket for your excavator?

Step 1: Choose a bucket type with soil conditions in mind

Step 2: Select a bucket style to suit your digging needs

Step 3: Add accessories to customize buckets

Step 4: Inspect wear items and replace parts

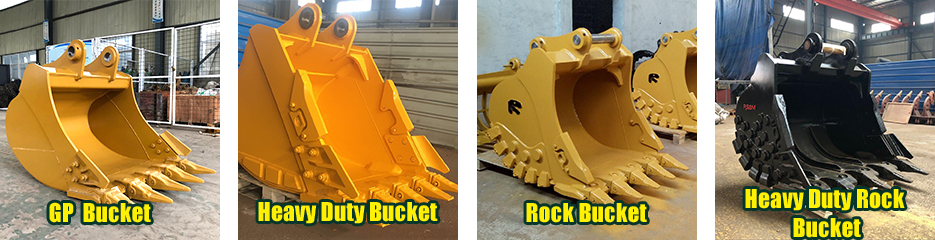

1.RSBM - GP bucket, with standard teeth, adapter, and side cutter

RSBM GP bucket is the most common excavator bucket type because they work well in earthwork. It is commonly used to excavate and load ordinary soil.

2.RSBM - HD bucket, with standard teeth, adaptor, double side cutter, reinforced plates on the bottom of the bucket.

RSBM HD bucket is an excavator bucket type with reinforced plates on the bottom of the bucket to prevent the stone and lumps in the soil from causing wear on the bucket.

3.RSBM - Rock bucket, with rock teeth, adaptor, double side protectors, lip protectors, and reinforced plates on the bottom of the bucket

RSBM rock bucket is a type of bucket with more protectors than GP bucket and HD bucket. It works well in a variety of soil conditions, such as clay, gravel, sand, silt, and shale. The buckets are manufactured with high-quality, abrasion-resistant material, durable side cutters for extra strength and protection, and bottom wear pads.

4.RSBM - Heavy Rock Bucket, with rock teeth, adaptor, double side protectors, lip protectors, heel shrouds, reinforced balls on both side of the bucket, and reinforced plates on the bottom of the bucket

RSBM HDR bucket is best suited for excavator operators who are handling abrasive materials in heavy or severe digging and truck-loading applications.

The buckets are manufactured with abrasion-resistant material for added protection and strength when digging in loose rock or pit and quarry operations. The buckets’ side cutters, shell bottoms, side wear plates, and weld-on wear shrouds all consist of abrasion-resistant material. In addition, reinforced gussets help strengthen the machine-fitting joints on the buckets to promote uptime.

Post time: May-11-2021